Injection Moulding

Continuous Improvements

From our East Anglia injection moulding facilities we continue to improve quality and efficiency, adapt and innovate by investing in new machinery and technology. Like the BOY 22 A V our newest small vertical machine injection moulding machines, used especially for the fully automatic encapsulation of inserts or for continuous production lines. We use mostly ‘Boy’ injection moulding machines.

From our East Anglia injection moulding facilities we continue to improve quality and efficiency, adapt and innovate by investing in new machinery and technology. Like the BOY 22 A V our newest small vertical machine injection moulding machines, used especially for the fully automatic encapsulation of inserts or for continuous production lines. We use mostly ‘Boy’ injection moulding machines.

Flexibility built-in

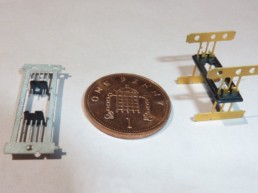

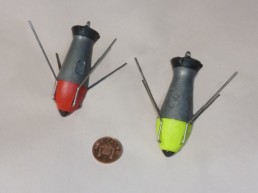

At Mumford Engineering we have built up a range of capacity options to fit our customers’ requirements, with 12 injection moulding machines ranging from 22 ton up to 150-ton capacity. We can produce a variety of plastic injection moulded parts weighing from less than 1 gram to 280 grams.

Plastic materials we use for the various injection moulded components produced.

We specialise in plastic injection mould tooling. Get in contact today for more information.

- ABS

- Fortron (Polyphenylene Sulfide)

- Nylon

- Glass filled Nylon

- Flame retardant Nylon

- Low density Polythene

- High density Polythene

- Polypropylene

- High impact styrene

- General purpose Styrene

- PVC

- Rubber

- Polycarbonate

- Glass filled polycarbonate

- Flame retardant polycarbonate

- Polyester

- Polycarbonate/ABS alloy

- Ultem (Polyetherimide)